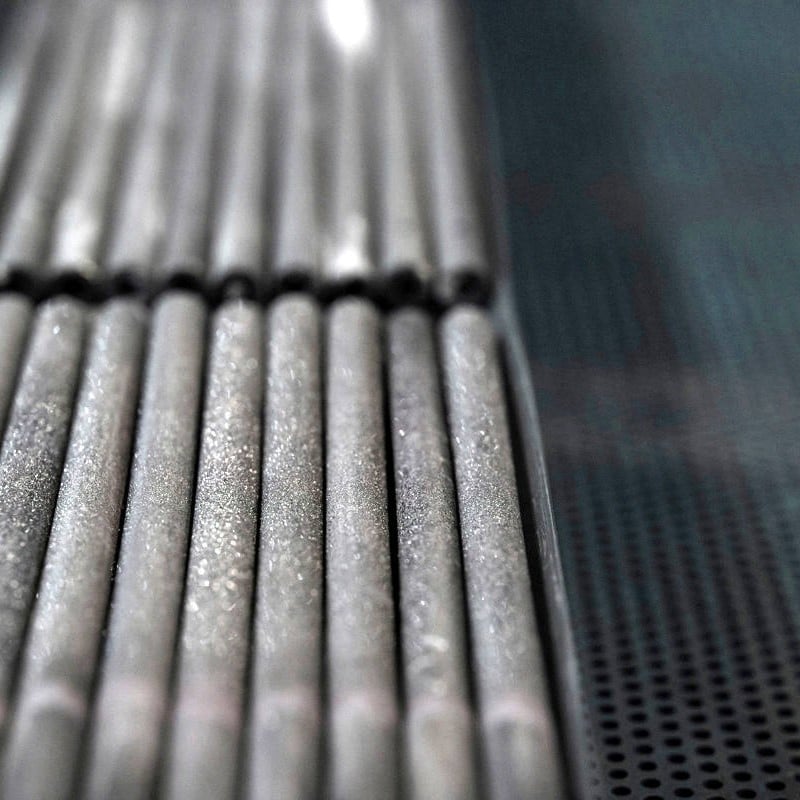

Globar® AS

Kanthal, leader mondial des éléments chauffants en carbure de silicium, propose Globar® AS, un produit phare de sa gamme. Cet élément chauffant à structure avancée bénéficie d'une répartition optimisée des particules et des pores, offrant une résistance mécanique, une cohérence et une résistance chimique inégalées. Les éléments Globar® AS offrent des performances améliorées dans les fours neufs et existants, offrant une plus grande durabilité et une plus grande efficacité opérationnelle. De plus, ils sont conçus pour un remplacement facile, ne nécessitant aucune modification de l'équipement ou des alimentations électriques existantes, ce qui rend les mises à niveau simples et efficaces dans diverses applications industrielles.

Informations

Applications

Les éléments Globar® AS conviennent à une variété d'industries, notamment :

- Industrie de l'aluminium primaire: Idéal pour les fours de maintien inclinables.

- Industrie du verre plat: Utilisé dans les éléments de flottage horizontaux.

- Industrie céramique et électronique: Appliqué dans les fours tunnel larges et dans la production de ferrite.

- Industrie sidérurgique: Efficace dans les lignes de recuit et de galvanisation en continu.

Caractéristiques

Avantages

Éléments de longue portée:

- Faible masse thermique pour une réponse plus rapide du four.

- Rendement du four amélioré.

- Zones chaudes jusqu'à 3,500 mm (137.8 po), avec des options plus longues disponibles.

Zone chaude monobloc:

- Idéal pour les fours plus larges, stimulant la productivité.

Installation simple:

- Ne nécessite aucun support supplémentaire, ce qui facilite le remplacement.

Légèreté par kW:

- Conception de four simplifiée.

Résistance aux chocs mécaniques:

- La structure avancée garantit des performances solides et fiables.

Fonctionnement cyclique :

- Réduit les temps d'arrêt, diminue les coûts de maintenance et améliore la productivité et l'efficacité globale de l'équipement (OEE).

Caractéristiques

Résistance mécanique supérieure: Globar® AS a un modulus de Weibull (une mesure de la répétabilité des propriétés mécaniques dans les matériaux cassants) de 14, offrant des éléments plus longs, plus légers et plus efficaces que les concurrents, généralement évalués en dessous de 10.

Optimisé pour une utilisation cyclique: Surpasse ses concurrents de plus de 40 % lors des tests cycliques à 1 425 °C (2 600 °F), prolongeant ainsi la durée de vie des éléments lors de fonctionnements intermittents.

Résistance chimique: Présente une structure à pores fermés qui limite la contamination et la pénétration de condensat, en particulier dans les environnements riches en alcalis comme la production de verre.

Durée de vie prolongée: Dans les applications à dépôt de verre important, les éléments Globar® AS durent jusqu'à 10 fois plus longtemps. Des éléments glacés en option offrent une protection supplémentaire.

Produits associés

D'autres produits qui pourraient vous intéresser