Shinsuke Ohara, president and founder of Oparz, makes sure every part of the 3D Heater is top quality.

Shinsuke Ohara, president and founder of Oparz, makes sure every part of the 3D Heater is top quality.

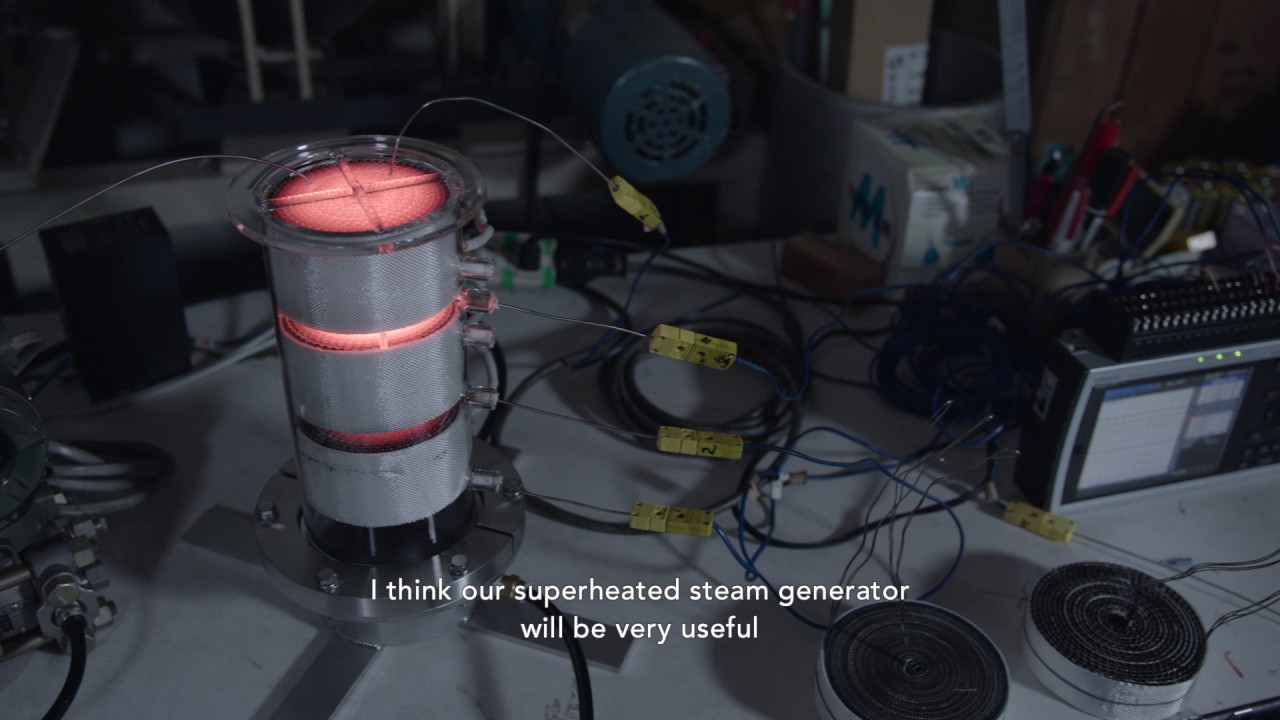

The 3D Heater developed by the Japanese company Oparz has never been more crucial to the present moment than in the current coronavirus pandemic. As part of the company’s Perfect Clean solution, which includes a blower and an air-cooled heat exchanger, the 3D Heater acts as a metal filter that effectively burns bacteria and virus into harmless ash, resulting in a sterile room for medical staff to work in.

At the core of the 3D Heater is a porous aggregate called Palblat. It is a metallic foil between 15 and 50 micrometers thick, processed with microscopic through-holes evenly throughout the foil and with burrs on both sides.

To form the 3D Heater, electrodes are attached before the Palblat is rolled into a coil and bound together using aluminum oxide tape. Depending on the application, the Palblat is either rolled with aluminum oxide tape in between layers of Palblat for insulation purposes, or without the aluminum oxide tape forming aluminum oxide directly on the flattened Palblat.

When used in the Perfect Clean solution, the 3D Heater is heated to at least 350 degrees Celsius, a temperature proven to be high enough to burn any dust, pollen, bacteria or virus into ashes.

To form the 3D Heater, the porous aggregate, called Palblat, is rolled into a coil and bound together using aluminum oxide tape.

To form the 3D Heater, the porous aggregate, called Palblat, is rolled into a coil and bound together using aluminum oxide tape.

High quality secures high safety

Material quality is of the utmost importance when your product aims to terminate infectious viruses, which is why Oparz has chosen to use the Kanthal® AF ferritic iron-chromium-aluminum alloy to produce its 3D Heater. The alloy is characterized by high oxidation resistance and good form stability, resulting in long element life.

“We have used the Kanthal AF alloy since 2017 and have found that its uniform heating performance is good,” says Shinsuke Ohara, president and founder of Oparz. “It has good stability as temperatures rise, and the constant heating mode works well.

“Someone might question why we don’t use ordinary stainless steel, considering that 350 degrees Celsius is a quite low temperature for Kanthal’s material,” he says. “Then we would reply that yes, we could use such material, but the product lifetime would be much shorter and the safety allowance on such material would be much lower.”

Oparz was a finalist for the 2016 Kanthal® Award. Watch our video here:

3D Heater applications

The 3D Heater technology has three main application areas:

- Liquid heating

Oparz has developed a superheated steam oven for cooking. - Gas heating

The Perfect Clean solution can be used for air purification and deodorization, applicable in hospital environments, food processing and more. - Metal heating

Surface heating applicable for solar power.

Related information

Read more about the Kanthal® AF alloy in our Product section.

How Oparz's 3D heater can be used in the fight against Covid-19.