Melters & holders

Customized electric furnace systems for melting, holding and transferring non ferrous alloys, including aluminum, magnesium, brass and tin, designed for long life and reliability. Typical temperature ranges are 1000-1300°C (1832-2372°F) but are application dependent. Specialty applications varied outside this range are possible.

- Customized to meet the requirements for each individual process

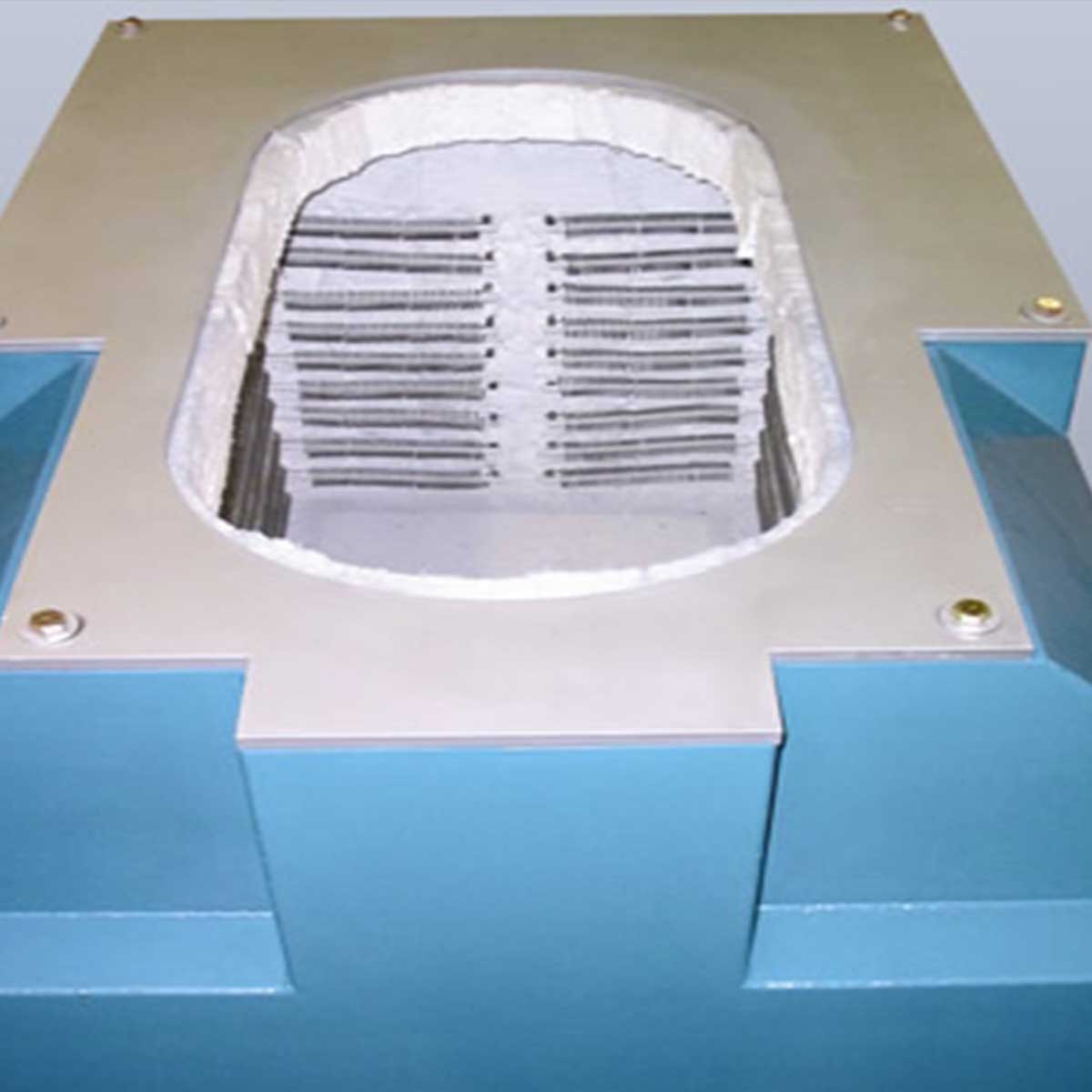

- Thermal efficient, high temperature fiber lining combined with high alumina cast refractory floor for minimal thermal losses

- Typical temperatures 1000-1300°C (1832-2372°F)

Information

In order to minimize thermal losses through furnace walls, thermally efficient, high temperature fiber lining is featured on the hot and cold chamber furnaces along with a high alumina cast refractory floor. Thus making the furnace melt capacity exceptionally high, resulting in larger production volumes for the customer.

PRODUCTS

- Melting furnaces

- Holding furnaces

- Crucible furnaces

- Heated lids

- Hot chamber furnaces

- Cold chamber furnaces

- Ingot preheaters

- Launder systems

Related products

Other products that might interest you