Globar® SG and SR

Globar® SG and SR silicon carbide heating elements offer high-performance solutions for challenging high-temperature applications. Produced through a unique reaction-sintering process, these elements feature exceptional oxidation resistance, durability, and consistent heating performance across a temperature range from 600°C (1,110°F) to 1,600°C (2,910°F).

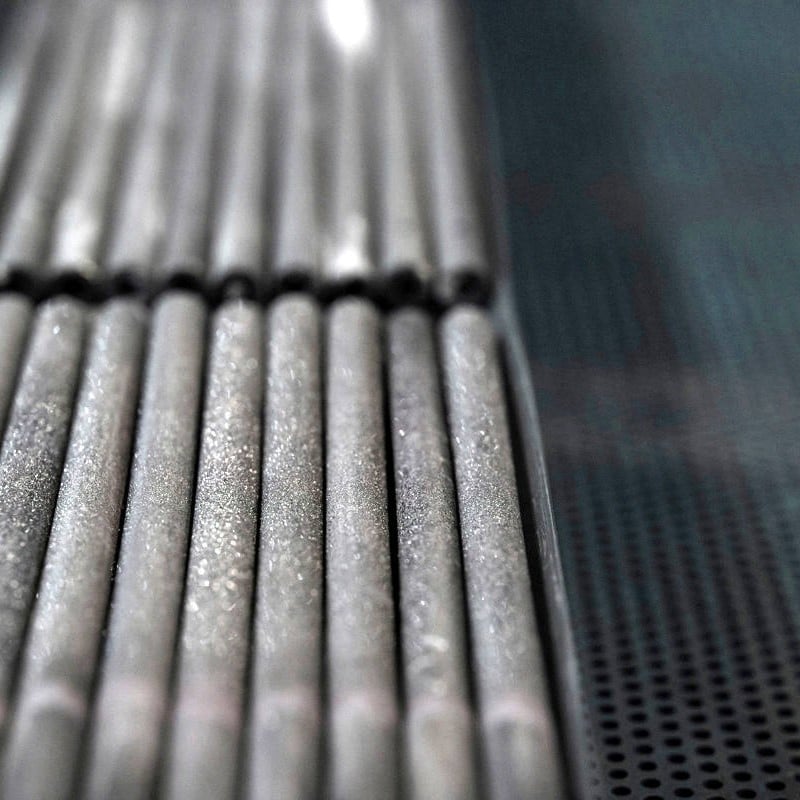

Globar® SG elements

Globar® SG elements include a central hot zone with two low-resistivity cold ends. This one-piece construction, with a helical cut in the hot zone, enables high resistance in the central area for efficient heat dissipation. Standard sizes range from 12 mm (0.47 in) to 54 mm (2.13 in) in diameter, with custom sizes up to 75 mm (2.95 in) available upon request. The cold ends stay relatively cool and are coated with aluminum for low-resistance connections, making installation straightforward.

Globar® SR elements

Globar® SR elements feature a two-start helical cut with the terminal assembly located at one end, allowing current to flow through one spiral and return via the second. These elements are ideal for applications requiring single-end connections and come in standard diameters from 12 mm to 54 mm, with larger sizes available on request. Equipped with short aluminum braids (or tags for smaller sizes), Globar® SR elements can be connected using Kanthal type Q high-purity, fully annealed aluminum braids for added flexibility.

Information

Applications

Globar® SG and SR elements are suited for a range of demanding industrial applications, including:

- Glass industry: Reliable heating for glass feeders and high-temperature furnaces.

- Ceramics: Effective for alumina ceramics, sintering, and component production.

- Electronics: High performance for electronics production and ferrite manufacturing.

- Metal Processing: Suitable for continuous annealing and galvanizing lines.

Related products

Other products that might interest you