Content:

Applications of load banks

Types of electric resistance heating alloys

Top-notch production process

Advantages of Kanthal® alloys

Design factors influencing the operational life of electric resistance heating alloys

Load banks are used in

Load banks in wind turbines

The role of Kanthal® alloys in wind turbine load banks

Kanthal® electric resistance heating alloys in wind power applications — for long-lasting and outstanding performance

Applications of load banks

Commissioning: Ensuring turbines meet operational specifications before going live.

Routine Testing: Regular checks to maintain high performance and detect potential failures.

Capacity Optimization: Adjusting system settings to maximize efficiency across varied operational conditions.

Operational Training: Simulate operational scenarios for training turbine technicians.

Emergency Preparedness: Test and prepare backup systems to ensure readiness.

Regulatory Compliance: Assist turbines in meeting stringent grid connectivity and stability standards.

Types of electric resistance heating alloys

Kanthal’s electric resistance heating alloys are divided into two primary categories based on their chemical makeup: ferritic (FeCrAl) and austenitic (NiCr), also known as non-ferritic alloys.

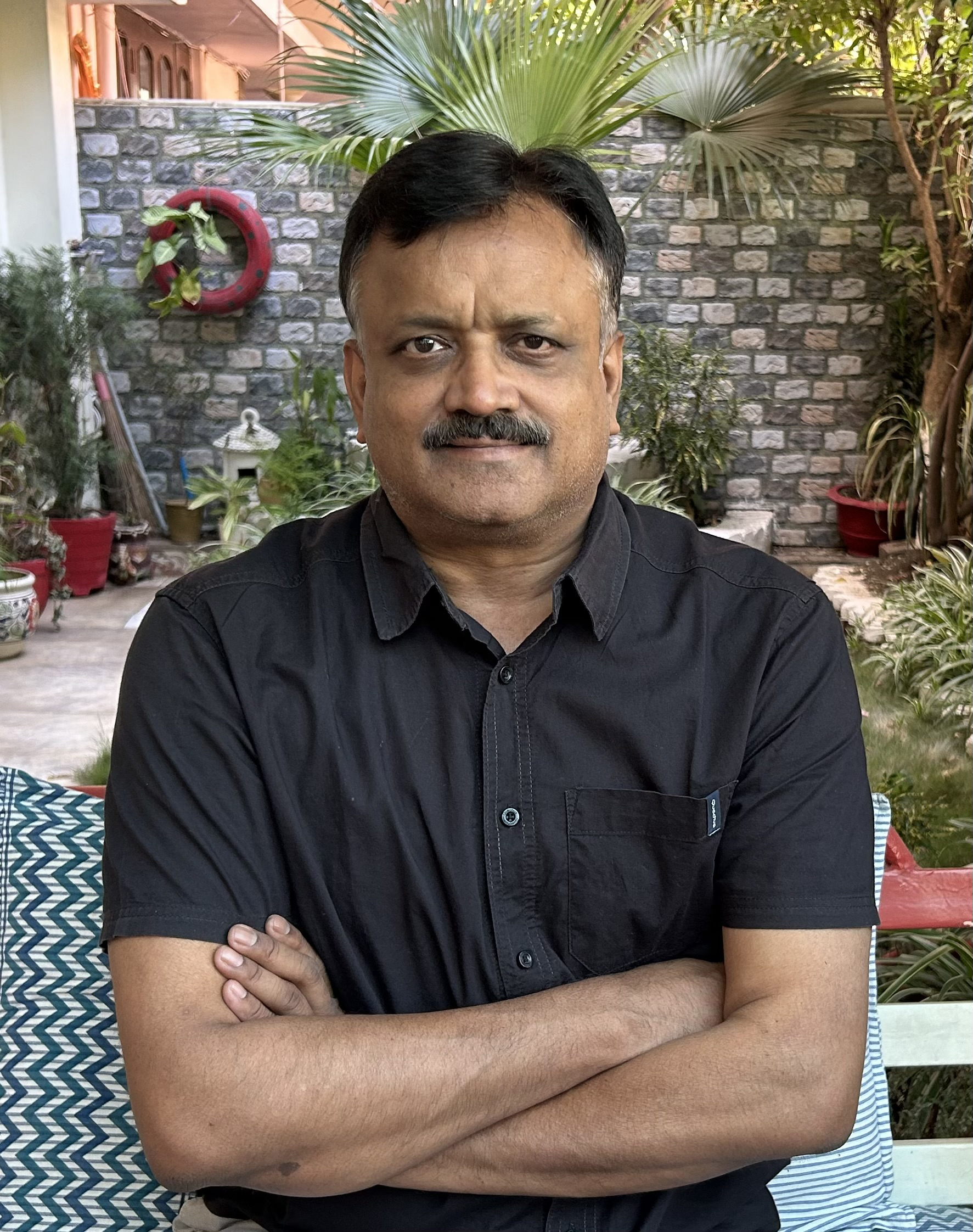

Praveen Gupta, Associate Vice President of Sales at Kanthal."Ferritic alloys are naturally inductive, making them ideal for scenarios where induction is beneficial, whereas austenitic alloys are better suited for applications requiring non-inductive materials. In situations where high power is needed in limited spaces, ferritic alloys are particularly effective," explains Praveen Gupta, Associate Vice President of Sales at Kanthal. He adds, "The effectiveness of an alloy's voltage regulation is also enhanced by its lower resistivity."

Praveen Gupta, Associate Vice President of Sales at Kanthal."Ferritic alloys are naturally inductive, making them ideal for scenarios where induction is beneficial, whereas austenitic alloys are better suited for applications requiring non-inductive materials. In situations where high power is needed in limited spaces, ferritic alloys are particularly effective," explains Praveen Gupta, Associate Vice President of Sales at Kanthal. He adds, "The effectiveness of an alloy's voltage regulation is also enhanced by its lower resistivity."

These alloys are characterized by their stable electrical resistivity, which remains consistent across a specified temperature range and can endure temperatures up to 1400°C (2552°F). This resilience makes them particularly effective for use in load banks, surpassing conventional resistance materials in durability, energy efficiency, and dependability.

"Our thorough approach ensures that our products maintain a reputation for exceptional reliability, from the initial identification of customer requirements to delivering consistently superior performance in a variety of applications," Gupta confirms.

Top-notch production process

The production of Kanthal alloys represents a pinnacle of advanced metallurgical engineering. The process begins with precise alloying techniques for both ferritic and non-ferritic (austenitic) materials, followed by controlled melting and extrusion methods. Every stage of production is carefully managed to ensure the alloys meet stringent quality standards. These processes guarantee that the alloys possess the necessary properties of resistivity, thermal stability, and mechanical strength, making them ideally suited for demanding applications such as load banks.

"Our manufacturing operations and research-driven processes are finely tuned with the final application in mind, enabling us to offer a broad spectrum of alloys. Each alloy is technically refined to comply seamlessly with international engineering standards," Gupta details.

Advantages of Kanthal® alloys

- Higher Maximum Temperature: Kanthal alloys can withstand temperatures up to 1425°C (2560°F).

- Increased Surface Load: Due to their ability to handle higher temperatures and longer lifespan, Kanthal alloys support higher surface loads, enhancing performance and durability.

- Wide Range of Resistivity: Kanthal alloys exhibit stable resistivity, allowing for the use of elements with larger cross-sections. This not only improves the lifespan of the element, especially in thin wire applications but also offers considerable weight savings.

- Superior Yield Strength: The higher yield strength of Kanthal alloys reduces changes in cross-section during wire coiling processes, ensuring consistent performance.

- Extended Lifespan: Kanthal alloys typically last 2–4 times longer than other resistance alloys under similar conditions, significantly reducing maintenance and replacement costs.

- Enhanced Oxidation Resistance: The formation of aluminum oxide (Al2O3) on Kanthal alloys acts as an effective diffusion barrier, improves electrical insulation, and offers superior resistance in saline atmospheres.

- Reduced Density: Kanthal ferritic alloys’ lower density means more elements can be accommodated in the same space, leading to lighter components and cost savings.

- Improved Corrosion Resistance to Sulfur: In environments with sulfuric compounds, Kanthal ferritic alloys demonstrate superior corrosion resistance, making them ideal for harsh conditions.

We hold extensive expertise in all facets of alloy application—from managing surface loads and current capacities to adapting to temperature variations and environmental conditions.

"Kanthal alloys offer unparalleled value by blending strong features and reliable performance with remarkable cost-effectiveness. Our comprehensive sales and distribution network ensures customers have direct access to our expert engineers, providing top-level application insights and proactive support for every project. We hold extensive expertise in all facets of alloy application—from managing surface loads and current capacities to adapting to temperature variations and environmental conditions—equipping our clients with the essential knowledge for the best alloy choice," Gupta states.

Design factors influencing the operational life of electric resistance heating alloys

The lifespan of electric resistance heating alloys depends on several key factors which vary by application. Here they are:

- Temperature & Temperature Cycling: High temperatures and frequent temperature variations significantly impact alloy durability.

- Contamination & Alloy Composition: Impurities and the specific composition of the alloy play critical roles.

- Physical Factors: Wire diameter, element geometry, surface condition, and mechanical stress also determine alloy longevity.

- Environmental Conditions: The atmosphere and the method of regulation tailored to the specific application are crucial.

- Oxidation Properties: Upon heating, resistance-heating alloys develop an oxide layer that protects against atmospheric attacks. For effective protection, this layer must be dense enough to resist gas and metal ion diffusion yet thin enough to adhere to the metal during temperature changes.

- Corrosion Resistance: Corrosive elements in the atmosphere significantly reduce wire life. Perspiration, mounting materials, and environmental contaminants contribute to corrosion. Specific environmental conditions also affect alloy performance:

- Steam and Halogens: These elements are particularly damaging, with halogens like fluorine and chlorine aggressively corroding high-temperature alloys at lower temperatures.

- Sulphur: Kanthal ferritic alloys perform well in sulfurous oxidizing gases.

- Salts and Oxides: High concentrations of alkaline metal salts and boron compounds are detrimental.

- Metals: Contact with molten metals such as zinc, brass, aluminum, and copper should be avoided as they react with the resistance alloys.

Support and Installation Considerations:

- Ceramic Support Materials: The choice of ceramic supports is vital, especially for high-temperature applications. Fire bricks should contain high alumina content, and iron oxide content should be minimized.

- Embedding Compounds: When using embedding compounds like ceramic fibers, materials such as alumina, alumina-silicate, magnesia, or zircon are recommended.

By understanding and managing these factors, the performance and lifespan of electric resistance heating alloys can be optimized, supporting the operational efficiency and durability of high-temperature applications.

Load banks are used in

- Engine Generators

- Battery Systems

- UPS Systems

- Aircraft Power Generators

- Ship Power Generators

- Wind Generators

- Hydro Generators

- Wind turbines

Load banks in wind turbines

Load banks are indispensable in the setup, maintenance, and functioning of wind turbines. They simulate artificial loads to assess turbine performance in controlled environments, ensuring the turbines are durable and dependable. This technology, long established, is now seeing renewed growth due to the rise in alternative power generation solutions. Comprising resistors, control systems, and fans to dissipate heat, load banks are available in various sizes to suit different needs.

The role of Kanthal® alloys in wind turbine load banks

Critical Energy Management

Kanthal® electric resistance heating alloys are integral in load banks for safely dissipating excess electrical energy as heat. This function is crucial during testing or system maintenance, ensuring equipment such as generators and UPS systems are protected from overloads while verifying their operational capabilities.

Design Flexibility

The versatility of Kanthal® alloys allows for custom resistor designs to meet specific requirements. Available in wire, ribbon, or strip form, these alloys are engineered to optimize heat dissipation, enhancing the efficiency and reliability of load banks across various electronics applications.

Integration with Control Systems

Kanthal-equipped load banks seamlessly integrate with electronic control systems, crucial for precise energy management. This integration ensures reliable performance and accurate testing environments, crucial for maintaining system integrity under variable operational conditions.

Kanthal® electric resistance heating alloys in wind power applications — for long-lasting and outstanding performance

|

Alloy |

Form |

Chemical Composition |

Characteristics |

|

Nikrothal® 40 |

NiCr |

|

|

|

Nikrothal® 60 |

NiCr |

|

|

|

Nikrothal® 80 |

NiCr |

|

|

|

Alkrothal® 14 |

FeCrAl |

|

|

|

Kanthal® D |

FeCrAl |

|

|

|

Alkrothal® 720 |

FeCrAl |

|

Read more

Our latest articles