Daniel Burton, Business Development Manager, KanthalGas burners have long been the traditional choice of heating solution for ladle preheating. This is despite their poor thermal efficiency since most of the heat generated is lost through exhaust gasses rather than used to heat the actual ladle. Not only does this increase energy costs, but also results in high emissions.

Daniel Burton, Business Development Manager, KanthalGas burners have long been the traditional choice of heating solution for ladle preheating. This is despite their poor thermal efficiency since most of the heat generated is lost through exhaust gasses rather than used to heat the actual ladle. Not only does this increase energy costs, but also results in high emissions.

“With gas burners, you’re releasing all these poisonous gasses into the factory and into the atmospheres, such as carbon dioxide, monoxide and nitrous oxides,” says Daniel Burton, Business Development Manager, Kanthal. “This is not only harmful for the environment but also creates a potentially hazardous working environment inside the factory.”

A cleaner, more efficient alternative

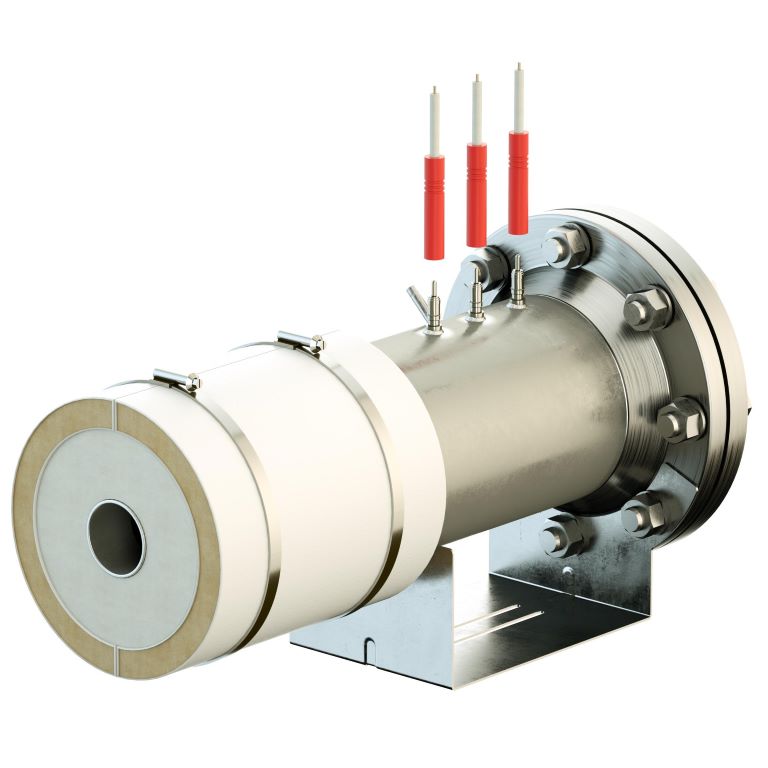

By replacing gas burners with electric heating, such as Kanthal’s Tubothal® and Kanthal® Flow Heater, aluminum producers can benefit from a huge improvement in thermal efficiency.

By replacing gas burners with electric heating, such as Kanthal’s Tubothal® and Kanthal® Flow Heater, aluminum producers can benefit from a huge improvement in thermal efficiency – from around 40 per cent up to over 95 per cent. This translates into an energy saving of around 60 per cent. Furthermore, all exhaust gasses and emissions are reduced to virtually zero.

“There are a whole host of environmental benefits to electric heating, namely the elimination of carbon dioxide emissions. But it also makes the factory a much safer, cleaner and quieter work environment,” adds Daniel. “You’re removing all the harmful gasses as well as reducing the noise levels significantly. On top of that, you can also free up a lot of space on the factory floor as you no longer need to reroute gas pipes and so on.”

Four benefits to using electric heating to preheat transport and bath ladles in primary aluminum production

- Improved efficiency. Since far less heat is lost through exhaust gasses, electric heating offers far greater efficiency than conventional gas heaters.

- Zero emissions. Electric heating generates no carbon dioxide emissions, significantly improving its environmental impact.

- Cleaner, quieter factory. By replacing gas burners with electric heating, you remove all harmful exhaust gasses, reduce noise levels, eliminate risks of explosion caused by gas and can contribute to a less cluttered working environment.

- Safer factory. Electric heating requires no combustion and offers an improved and repeatable process. Because no water vapor is produced in the process, the potential for water vapor explosions is greatly reduced.

Connected products

Here you can find the Kanthal product offering

Learn from our experts

Our latest articles